As the main PVB interlayer production center of Aotianli, our production base is equipped with domestic advanced automated production equipment and intelligent control system to ensure stable production. We plan to add one new intelligent production line, which will increase our annual production capacity to 16,000 tons. The strong capacity reserve ensures fast delivery of customer orders and efficient matching of supply chain demand.

Home / Precision Manufacturing

Precision PVB Film Manufacturing

Advantages

-

0Acres

Cover An Area

-

0tons

Annual Capacity

-

0

PVB Intermediate Film Production Line

Raw Material Security

The company operates its own PVB resin powder production base at Jiangxi Tianhui New Material Co. Supported by advanced materials technology, we have achieved full industry chain coverage from raw materials to intermediate films, significantly enhancing supply chain stability and product competitiveness.

PVB Resin Powder Production Process:

- Polymerizing

- Dissolving

- Drying

- Sieving & Packaging

Precision Process

Intelligent production management system

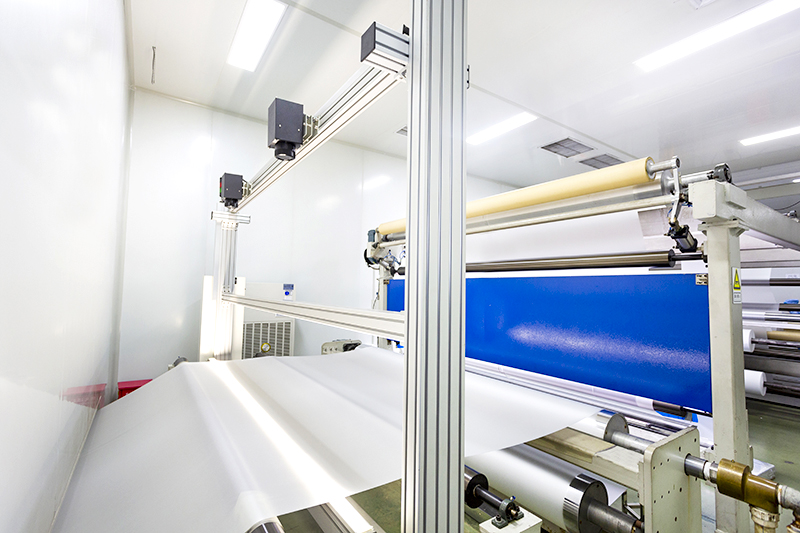

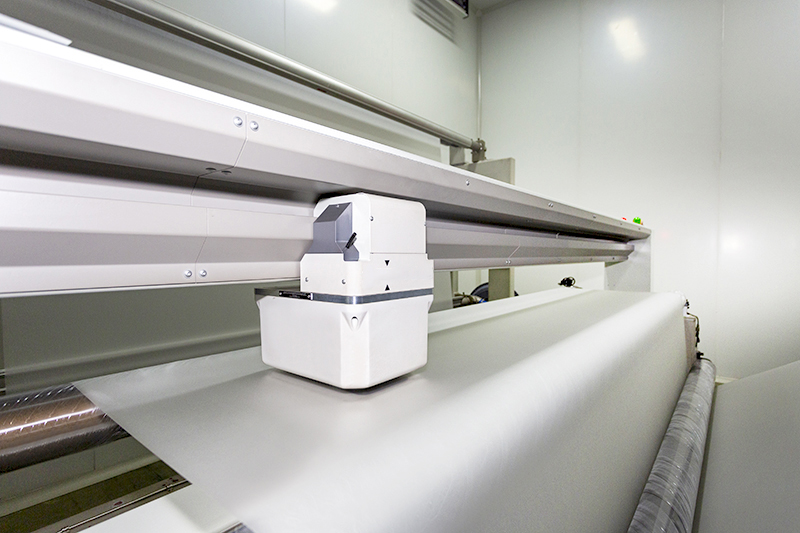

Constant temperature and humidity dust-free winding process is adopted, and the cleanliness of the environment is up to 10,000 grade standard, which ensures high optical performance and stability of the products.

The ERP system is deeply integrated, realizing minute-level data synchronization from raw material entering the warehouse to finished product leaving the warehouse.

Production Process

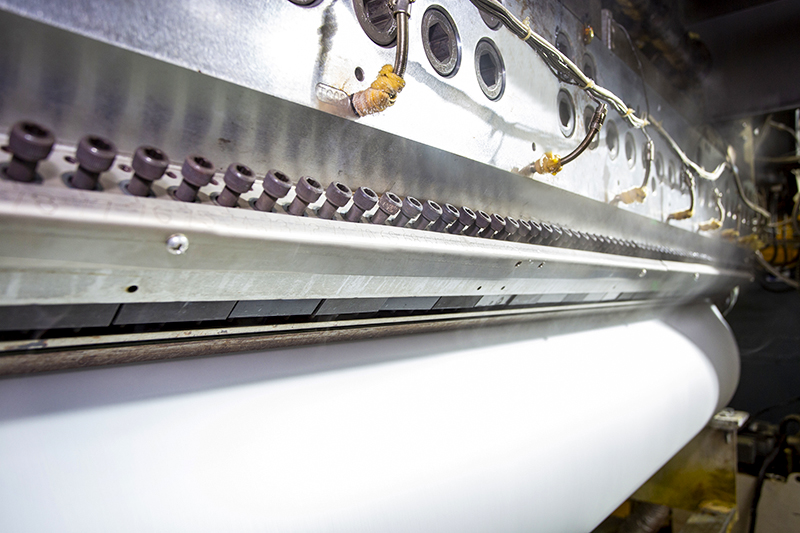

Our production process involves a number of complex procedures to ensure that the finished PVB products have reliable optical and mechanical properties.

- Ingredient process 01

- Mixing and extrusion process 02

- Casting and cooling process 03

- Winding and packaging 04

Production Workshop

English

English 中文简体

中文简体