As the global renewable energy market continues its rapid expansion, the solar industry remains at the forefront of technological innovation. One of the lesser-known yet crucial materials driving improvements in solar module performance and longevity is the Photovoltaic Grade PVB (Polyvinyl Butyral) Interlayer Film. Traditionally used in the automotive and architectural glass industries for its excellent adhesion and safety properties, PVB has now found a new and vital role in photovoltaic (PV) glass laminates. This material is helping to make solar panels not only more durable but also more efficient and aesthetically appealing.

1. Enhanced Adhesion and Structural Integrity

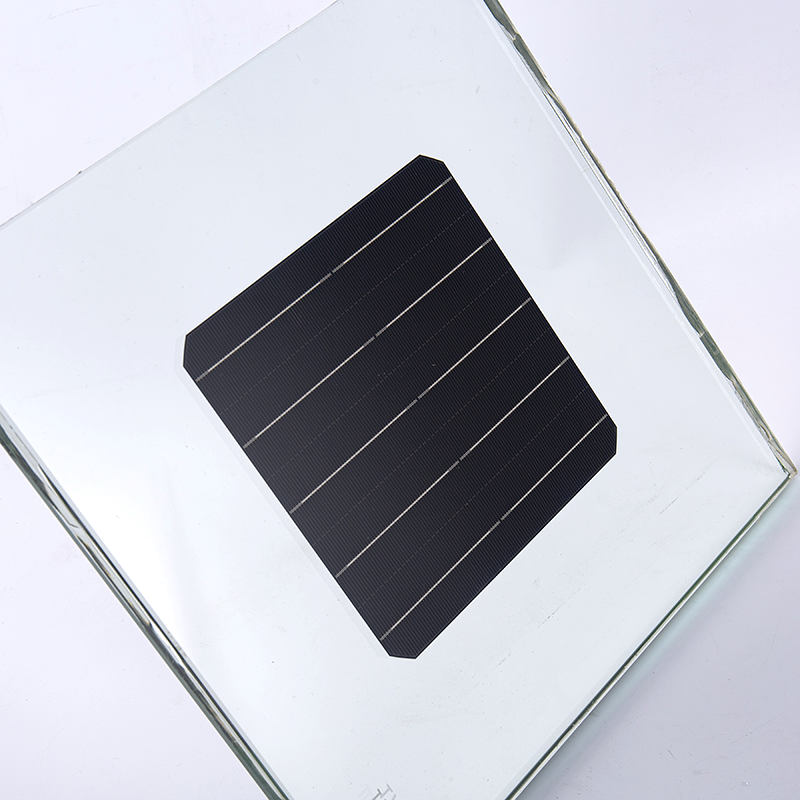

One of the primary advantages of using PVB interlayer film in photovoltaic glass laminates is its outstanding adhesion to glass and encapsulated materials. The film forms a strong bond between the layers of tempered glass and solar cells, ensuring that the laminated module remains intact even under severe environmental stress. This strong adhesion prevents delamination—a common issue in solar modules that can lead to moisture ingress and performance degradation.

Compared to traditional encapsulants such as EVA (Ethylene Vinyl Acetate), PVB offers superior interlayer cohesion and impact resistance, making it ideal for applications in building-integrated photovoltaics (BIPV) where both safety and durability are paramount.

2. Superior Optical Clarity and Light Transmission

Photovoltaic Grade PVB films are engineered to have high optical transparency, allowing maximum light transmission to the solar cells. The clarity of PVB ensures that sunlight passes through with minimal reflection or scattering, enhancing the overall efficiency of the solar module.

Some advanced PVB formulations can achieve light transmittance rates above 90%, comparable to or even surpassing other encapsulant materials. This makes them particularly suitable for double-glass modules and transparent PV panels used in solar facades, skylights, and greenhouses, where both energy generation and aesthetic appeal are important.

3. Excellent UV Resistance and Weather Durability

Outdoor solar installations are constantly exposed to harsh environmental conditions including ultraviolet (UV) radiation, temperature fluctuations, humidity, and wind. PVB interlayer films are specifically designed to resist UV degradation, maintaining their optical and mechanical properties over decades of use.

This weather durability ensures that the photovoltaic glass laminate remains stable, preventing yellowing, delamination, or cracking over time. PVB’s chemical structure provides long-term resistance to both photochemical degradation and thermal oxidation, which are key factors in extending the lifespan of solar panels.

4. Enhanced Safety and Impact Resistance

PVB interlayer films were originally developed for safety glass applications due to their excellent impact absorption and shatter prevention capabilities. When applied in photovoltaic glass laminates, these properties provide an extra layer of protection against mechanical damage, such as hail impact or accidental breakage.

In the event of glass fracture, the PVB layer holds the broken pieces together, preventing scattering and maintaining the integrity of the module. This makes it ideal for installations in high-risk areas—such as rooftops, facades, or public spaces—where safety is a key concern.

5. Superior Moisture Barrier and Electrical Insulation

Another major advantage of PVB films is their low moisture permeability, which significantly reduces the risk of water ingress into the photovoltaic module. Moisture is one of the leading causes of corrosion in solar cells and electrical connections. By acting as a barrier, PVB helps to preserve electrical insulation and prevent potential-induced degradation (PID).

This enhanced sealing property not only extends the module’s service life but also ensures stable power output under humid or coastal environmental conditions.

6. Design Flexibility and Aesthetic Applications

With the rise of Building-Integrated Photovoltaics (BIPV), architects and developers are seeking materials that combine energy generation with visual appeal. PVB interlayer films offer design flexibility, as they can be manufactured in a variety of colors, transparencies, and thicknesses.

This makes it possible to create custom solar glass laminates that blend seamlessly with modern architecture while still delivering high energy performance. Colored or frosted PVB films can even help reduce glare and improve visual comfort in interior spaces.

7. Thermal and Acoustic Benefits

In addition to optical and mechanical advantages, PVB interlayer films also contribute to the thermal insulation and soundproofing of photovoltaic structures. The film’s viscoelastic properties absorb vibrations and reduce noise transmission, which can enhance the comfort of buildings using BIPV systems.

This dual functionality allows solar glass panels to serve as both energy generators and building envelope materials, improving overall efficiency and sustainability in architectural design.

8. Environmentally Friendly and Recyclable

As sustainability becomes a central focus in manufacturing, modern PVB formulations are increasingly developed with eco-friendly additives and recyclable content. Some manufacturers are now producing PVB films from recycled automotive glass, closing the loop in material usage and reducing carbon footprints.

The use of PVB interlayer film aligns perfectly with the green energy mission of the solar industry—helping not only to generate clean power but also to do so through sustainable materials and processes.

9. Growing Market Demand and Industry Outlook

The market for photovoltaic-grade PVB interlayer films is expanding rapidly, driven by the increasing adoption of double-glass PV modules and BIPV solutions. According to recent industry reports, global demand for PVB in solar applications is expected to grow at a compound annual growth rate (CAGR) of over 10% in the coming years.

Major glass and film manufacturers are investing heavily in the development of advanced PVB materials with improved UV resistance, higher transparency, and longer lifespan, catering to the evolving needs of high-efficiency solar modules.

10. Conclusion

The integration of Photovoltaic Grade PVB Interlayer Film into solar glass laminates marks a significant step forward in both performance and reliability. Its combination of optical clarity, mechanical strength, weather resistance, and safety features makes it an ideal choice for the next generation of photovoltaic systems.

As solar technology continues to evolve toward greater efficiency and sustainability, PVB interlayer films will play a crucial role in ensuring that photovoltaic glass not only captures more sunlight but also stands the test of time—offering a durable, safe, and environmentally responsible solution for the global renewable energy industry.

English

English 中文简体

中文简体