The growing demand for renewable energy has made photovoltaic (PV) solar panels an essential component of modern energy infrastructure. A critical element in the construction of these panels is the photovoltaic grade PVB (polyvinyl butyral) interlayer film, which plays a crucial role in ensuring module efficiency, durability, and longevity. Unlike standard PVB films used in architectural or automotive laminated glass, photovoltaic grade PVB is specially formulated to withstand harsh environmental conditions, resist UV degradation, and maintain optical and mechanical performance over decades of service.

Choosing the right PVB interlayer is essential for solar panel manufacturers, as it directly affects module efficiency, structural integrity, and long-term reliability. This article explores the key factors to consider when selecting photovoltaic grade PVB for solar applications, including mechanical properties, optical clarity, thermal performance, chemical resistance, and compatibility with solar cell technologies.

1. Optical Clarity and Transparency

One of the most critical factors in selecting photovoltaic grade PVB is optical performance. Solar panels rely on the transmission of sunlight to the underlying photovoltaic cells, and any reduction in light transmission can negatively impact energy conversion efficiency. When evaluating PVB films, manufacturers should consider:

High Transparency: Photovoltaic grade PVB should allow over 90% visible light transmittance to minimize energy loss.

Low Haze: A low haze factor ensures that light is transmitted directly to the solar cells rather than scattered, preserving the panel’s efficiency.

UV Stability: The interlayer must resist yellowing and degradation caused by prolonged UV exposure, which can reduce clarity over time.

Maintaining optical clarity is especially important in regions with high solar irradiance, where even minor reductions in light transmission can significantly affect energy output.

2. Mechanical Strength and Durability

Photovoltaic modules are subjected to various mechanical stresses, including wind load, hail impact, and thermal expansion/contraction. The PVB interlayer must contribute to the overall structural integrity of the module. Key mechanical considerations include:

Tensile Strength: The PVB film should resist tearing during lamination and in-field service.

Elasticity and Flexibility: Flexible interlayers accommodate differential expansion between glass and solar cells without causing cracking or delamination.

Impact Resistance: The interlayer should absorb and distribute energy from impacts, such as hailstones, protecting both the glass and the solar cells.

Long-Term Creep Resistance: The film should maintain its mechanical properties over decades without significant deformation under sustained stress.

By ensuring mechanical durability, manufacturers can produce PV modules that withstand extreme weather and maintain performance over the expected 25-30 year service life.

3. Thermal and Heat Resistance

Solar panels are exposed to fluctuating temperatures, which can range from sub-zero winters to hot summer afternoons. Photovoltaic grade PVB must maintain performance under these conditions:

High Thermal Stability: PVB should tolerate lamination temperatures during production (typically 140–160°C) and resist degradation under operational heat.

Low Thermal Expansion: Minimal thermal expansion prevents stress on solar cells and the glass interlayer, reducing the risk of micro-cracks.

Retention of Mechanical Properties at High Temperatures: The film should remain strong and flexible even in hot climates.

Selecting PVB with excellent thermal performance ensures that modules continue to function efficiently without warping, delamination, or micro-cracking.

4. Chemical and Moisture Resistance

Photovoltaic modules are exposed to moisture, humidity, and chemical pollutants, which can degrade materials over time. The PVB interlayer must provide barrier protection to the solar cells:

Moisture Resistance: Prevents water ingress that can cause corrosion of electrical components or delamination.

Chemical Stability: Resistant to acids, bases, and airborne pollutants that could accelerate degradation.

Adhesion to Glass and Solar Cells: Strong adhesion ensures long-term integrity, even under humid or chemically aggressive conditions.

These properties are essential for maintaining reliable module performance in coastal, industrial, or tropical environments.

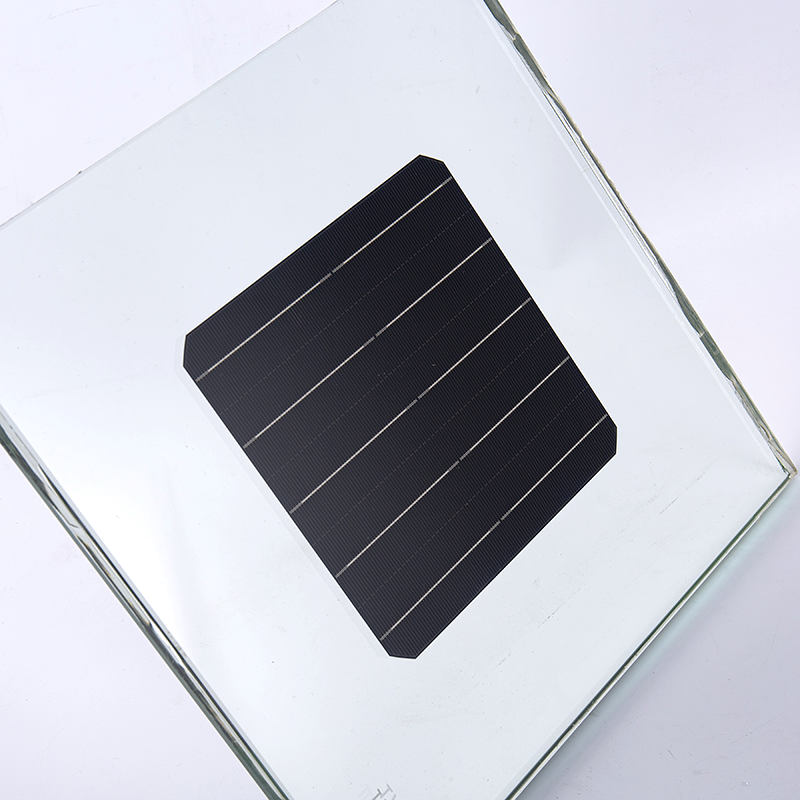

5. Compatibility with Different Solar Cell Technologies

Photovoltaic panels use various types of solar cells, each with specific requirements. PVB interlayers must be compatible with the intended technology:

Crystalline Silicon (c-Si) Cells: Require high optical clarity and strong adhesion for mechanical support.

Thin-Film Solar Cells (e.g., CIGS, CdTe): May require PVB formulations optimized for low-temperature lamination or enhanced UV stability.

Bifacial Modules: Demand interlayers with minimal light absorption to allow sunlight to pass through the rear of the panel.

Understanding the specific cell technology helps manufacturers choose a PVB film that maximizes efficiency and module longevity.

6. Laminating Performance

The lamination process itself is a critical factor in selecting photovoltaic grade PVB. The interlayer must perform well during production to avoid defects:

Bubble-Free Lamination: High-quality PVB films should not trap air pockets during lamination.

Flow and Softening Characteristics: The film should soften appropriately under heat and pressure to ensure complete bonding between layers.

Dimensional Stability: The interlayer should not shrink excessively during lamination, preventing stress or distortion.

Uniform Thickness: Ensures consistent mechanical and optical performance across the module.

Optimized laminating performance reduces production defects and improves overall module reliability.

7. Long-Term Stability and Durability

Photovoltaic modules are expected to operate efficiently for 25 years or more. PVB interlayers must maintain their properties throughout this period:

Resistance to Yellowing: Prevents optical degradation that could reduce energy output.

Resistance to Delamination: Ensures the interlayer remains bonded to both glass and solar cells despite thermal cycling, humidity, and mechanical stress.

Retention of Adhesion and Flexibility: Maintains structural integrity and protects the module from environmental stresses.

Long-term durability is critical to minimize maintenance, replacements, and warranty claims.

8. Regulatory and Industry Standards

Choosing PVB for photovoltaic applications also requires consideration of industry standards and certifications:

IEC 61730: Safety standards for PV modules.

IEC 61215: Performance testing standards for crystalline silicon PV modules.

UL 1703 / UL 61730: North American safety certifications.

ISO Standards: Relevant to material quality and environmental testing.

Selecting PVB films that comply with these standards ensures global market acceptance and product reliability.

9. Cost-Effectiveness and Supply Reliability

While performance is critical, manufacturers must also consider economic factors:

Material Cost vs. Performance: High-performance PVB may be more expensive, but it can reduce warranty claims and improve long-term module efficiency.

Supply Stability: Reliable sourcing prevents production delays.

Consistency in Quality: Uniform PVB properties are essential to avoid variability in module performance.

Balancing cost with high-quality performance ensures both economic viability and product reliability.

10. Environmental Considerations

As the solar industry promotes sustainability, PVB selection should also factor in environmental impact:

Recyclability: Some PVB formulations can be recovered and reused at the end of module life.

Low Environmental Footprint: Manufacturers increasingly prefer interlayers with minimal volatile organic compounds (VOCs) and eco-friendly production methods.

Contribution to Energy Efficiency: Effective thermal and optical performance contributes to cleaner energy production over the module’s lifetime.

These considerations support green energy goals and corporate sustainability initiatives.

Conclusion

Choosing the right photovoltaic grade PVB interlayer film is a critical decision in solar module manufacturing, affecting energy efficiency, durability, and long-term reliability. Key factors include:

Optical clarity and transparency for maximum light transmission.

Mechanical strength and durability to resist environmental stress.

Thermal and heat resistance for stable performance under fluctuating temperatures.

Chemical and moisture resistance to protect solar cells from corrosion and degradation.

Compatibility with solar cell technologies, including crystalline silicon and thin-film cells.

Laminating performance to ensure defect-free production.

Long-term stability and durability for 25+ years of operation.

Compliance with regulatory standards for safety and performance.

Cost-effectiveness and supply reliability for sustainable production.

Environmental considerations supporting sustainability initiatives.

By carefully evaluating these factors, manufacturers can select the optimal PVB interlayer, producing photovoltaic modules that deliver high efficiency, long service life, and reliable performance, while meeting both commercial and environmental requirements.

English

English 中文简体

中文简体