In the rapidly expanding solar energy industry, one crucial yet often overlooked component is the encapsulation material—the layer that protects solar cells from mechanical damage, moisture, and UV degradation while maintaining light transmission. Among various encapsulation options, PVB (Polyvinyl Butyral) Photovoltaic Grade has become a preferred solution for high-performance solar panels due to its excellent optical clarity, adhesion, and durability.

This article explores the properties, benefits, and applications of PVB photovoltaic-grade film, and compares it with other encapsulation materials to help manufacturers, engineers, and project developers make informed choices.

What Is PVB Photovoltaic Grade?

PVB (Polyvinyl Butyral) is a thermoplastic resin made by reacting polyvinyl alcohol with butyraldehyde. While it is widely known for its use in laminated safety glass for automotive and architectural applications, a photovoltaic-grade PVB film is specially formulated to meet the performance demands of solar module encapsulation.

Compared to general-purpose PVB, the photovoltaic grade has enhanced UV stability, moisture resistance, and adhesion strength to glass and solar cells, making it suitable for long-term outdoor exposure. It also maintains high optical transmittance, ensuring that sunlight can reach the photovoltaic cells without significant energy loss.

Key Features of PVB Photovoltaic Grade Film

-

High Optical Transmission

PVB photovoltaic film allows more than 90% light transmittance, enabling maximum solar energy absorption by the cells. -

Excellent Adhesion

Strong bonding to both glass and solar cells helps prevent delamination, even after years of outdoor exposure. -

Superior Weather Resistance

With UV stabilizers and anti-aging properties, PVB films can maintain performance in hot, humid, and high-UV environments. -

Impact Resistance

PVB film enhances the mechanical durability of solar modules, reducing breakage from hail, debris, or handling. -

Moisture Barrier

It slows down water ingress, protecting the internal components from corrosion and electrical degradation. -

Flexible Processing

PVB can be laminated using standard vacuum lamination equipment, making it a versatile choice for module manufacturers.

Applications in the Solar Industry

PVB photovoltaic-grade films are used primarily as an encapsulation layer in glass–glass solar modules, where their strength and adhesion properties provide long-term protection. Typical applications include:

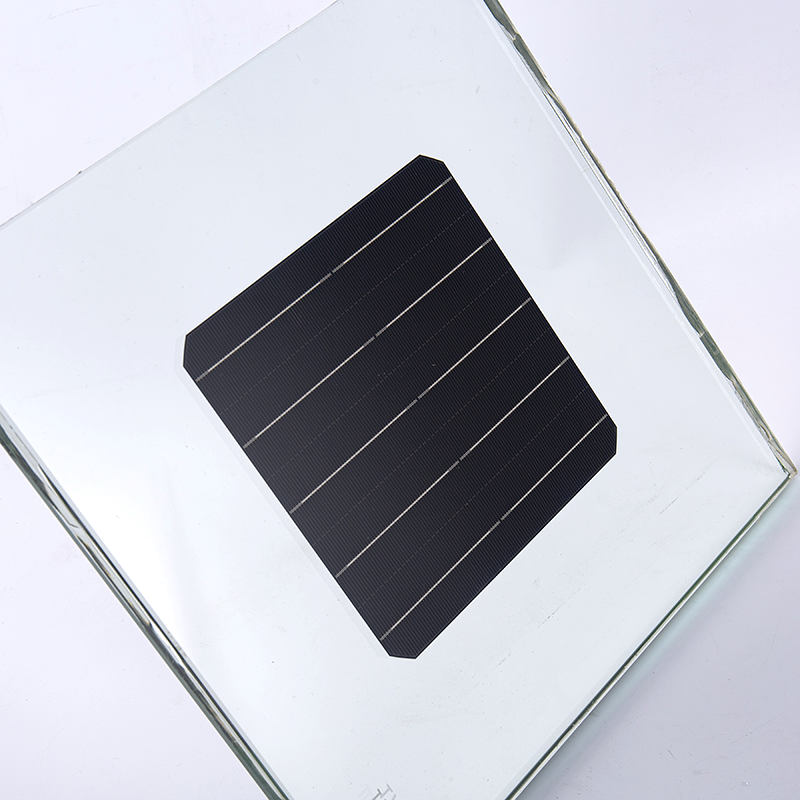

- Crystalline Silicon Solar Panels – For both residential and commercial installations.

- BIPV (Building Integrated Photovoltaics) – Especially in glass façade applications.

- Thin-Film Solar Modules – Where mechanical protection and optical clarity are critical.

- Solar Greenhouse Panels – Providing transparency and UV control.

Comparison Table: PVB Photovoltaic Grade vs. EVA vs. POE

| Feature / Property | PVB Photovoltaic Grade | EVA (Ethylene-Vinyl Acetate) | POE (Polyolefin Elastomer) |

|---|---|---|---|

| Light Transmittance | ≥ 90% | 88–90% | 88–90% |

| Adhesion to Glass | Excellent | Good | Good |

| Moisture Resistance | Good | Moderate | Excellent |

| UV Resistance | Excellent | Good | Excellent |

| Impact Resistance | High | Medium | High |

| Processing Temperature | 110–150°C | 140–150°C | 140–150°C |

| Typical Application | Glass–Glass PV Modules, BIPV | Glass–Backsheet PV Modules | Glass–Glass & Bifacial PV |

| Cost | Medium–High | Low | Medium–High |

Advantages of PVB Photovoltaic Grade for Solar Panels

-

Extended Module Lifespan

With strong adhesion and weather resistance, PVB encapsulated modules can last 25–30 years with minimal performance loss. -

Enhanced Safety

Similar to automotive laminated glass, PVB improves impact resistance and prevents shattering, making panels safer in public spaces. -

Aesthetic Quality

PVB films offer excellent optical clarity, which is beneficial for BIPV projects where transparency and appearance matter. -

Better Performance in Harsh Environments

Especially suited for tropical or high-humidity climates where EVA may degrade faster. -

Compatibility with Glass–Glass Structures

Ideal for bifacial modules and glass façade solar systems, providing structural integrity without compromising light penetration.

Processing and Lamination Tips

- Surface Preparation – Ensure glass and cell surfaces are clean and free from dust or oil before lamination.

- Controlled Lamination Conditions – Use recommended temperature and vacuum cycle to ensure proper adhesion.

- Edge Sealing – Consider adding an edge sealant for improved moisture barrier performance.

- Storage – Keep PVB films in a cool, dry environment to avoid premature curing or moisture absorption.

Future Outlook for PVB Photovoltaic Grade

With the growing adoption of glass–glass PV modules and BIPV projects, the demand for PVB photovoltaic-grade film is expected to rise steadily. As manufacturers develop advanced formulations with improved moisture barriers and lower processing temperatures, PVB could expand its role beyond premium installations into mainstream solar panel production.

Moreover, as aesthetic solar glass applications (such as colored or patterned panels) gain popularity, PVB’s optical performance and customization options will become even more valuable.

Conclusion

PVB Photovoltaic Grade is more than just an encapsulation material—it’s a long-term investment in the durability, efficiency, and safety of solar panels. Its unique combination of high transparency, strong adhesion, impact resistance, and weather durability makes it particularly suitable for glass–glass solar modules and architectural BIPV applications.

For solar manufacturers seeking to differentiate their products and deliver superior performance over decades, adopting PVB photovoltaic-grade encapsulation could be the competitive edge they need.

English

English 中文简体

中文简体