Understanding Photovoltaic Grade PVB Interlayer Film

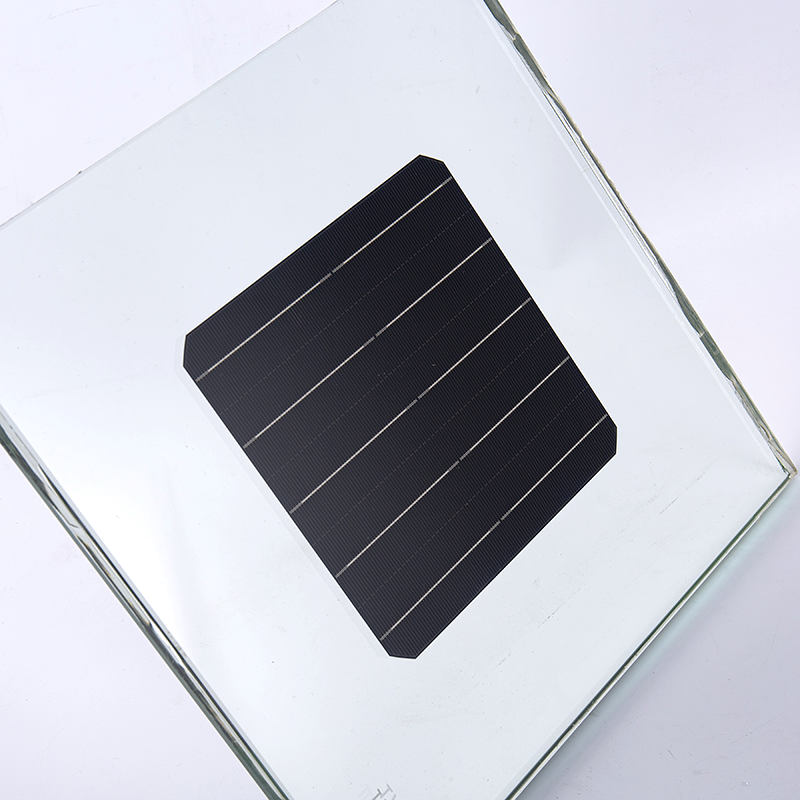

Polyvinyl butyral (PVB) interlayer film serves as a critical component in solar photovoltaic modules, providing essential lamination properties that ensure long-term performance, safety, and durability. Unlike standard architectural or automotive PVB films, photovoltaic grade PVB interlayer films must meet stringent requirements specific to solar energy applications, including exceptional optical clarity, superior adhesion to solar cells and glass substrates, excellent moisture resistance, and the ability to withstand decades of exposure to ultraviolet radiation, temperature cycling, and environmental stress without degradation.

The selection of appropriate PVB interlayer film significantly impacts solar module performance, reliability, and lifespan. High-quality photovoltaic grade PVB creates robust encapsulation that protects delicate solar cells from moisture ingress, mechanical stress, and environmental contamination while maintaining optimal light transmission to maximize energy generation. As the solar industry continues advancing with higher efficiency cells, larger module formats, and more demanding installation environments, understanding the characteristics, specifications, and selection criteria for PVB interlayer films becomes increasingly important for manufacturers, installers, and project developers seeking to optimize solar investments.

Key Performance Characteristics of PVB Interlayer Films

Photovoltaic grade PVB interlayer films must satisfy multiple performance criteria simultaneously, balancing optical, mechanical, chemical, and thermal properties to ensure reliable solar module operation throughout their expected 25-30 year service life. Understanding these characteristics helps in selecting films appropriate for specific module designs and deployment environments.

Optical Transparency and Light Transmission

Maximum light transmission represents the most fundamental requirement for photovoltaic PVB films, as any reduction in transmitted light directly decreases energy generation. Premium photovoltaic grade PVB films achieve light transmittance exceeding 90% across the visible and near-infrared spectrum, with the best products reaching 91-92% transmittance. This high transparency must remain stable throughout the module's lifetime, resisting yellowing or hazing that would progressively reduce energy output. The film's refractive index, typically around 1.48-1.49, closely matches glass and ethylene-vinyl acetate (EVA) encapsulants, minimizing reflection losses at material interfaces.

Low haze values, typically below 1%, ensure that transmitted light maintains directionality rather than scattering, which would reduce the effective light reaching solar cells. Manufacturers specify both initial optical properties and retention after accelerated aging tests that simulate years of outdoor exposure, with minimal change indicating superior long-term stability. Some advanced PVB formulations incorporate UV absorbers or stabilizers that protect underlying solar cells from harmful short-wavelength radiation while maintaining transparency in the energy-producing wavelengths.

Adhesion Properties and Bonding Strength

Strong, durable adhesion to both glass surfaces and solar cell materials is essential for maintaining module integrity throughout its operational lifetime. PVB interlayer films must bond reliably to tempered glass front sheets, solar cell metallization, backsheets, and any other module components during the lamination process while resisting delamination under thermal cycling, humidity exposure, and mechanical stress. Adhesion strength is typically measured in N/cm using peel tests, with photovoltaic grade films requiring minimum values of 20-40 N/cm depending on specific application requirements and testing protocols.

The adhesion mechanism involves both physical interlocking at the molecular level and chemical bonding facilitated by hydroxyl groups in the PVB polymer structure. Proper lamination process control—including temperature profiles, vacuum levels, and pressure application—activates these adhesion mechanisms. Some PVB films incorporate adhesion promoters or surface treatments that enhance bonding to specific substrate materials, particularly important for specialized cell technologies or novel backsheet materials emerging in advanced module designs.

Moisture Barrier Performance

Moisture represents one of the primary degradation mechanisms for solar modules, causing corrosion of cell metallization, delamination, and electrical performance losses. While PVB naturally possesses moderate moisture barrier properties, photovoltaic grade films optimize formulations to minimize water vapor transmission rates (WVTR). Typical WVTR values for PV-grade PVB range from 15 to 30 g/m²/day at standard test conditions (38°C, 90% relative humidity), though this varies with film thickness and specific formulation.

The moisture barrier performance must complement other encapsulation components, particularly edge sealants and backsheet materials, to create a complete moisture protection system. In high-humidity deployment environments or marine installations, selecting PVB films with superior moisture resistance becomes particularly critical. Some manufacturers offer dual-layer lamination systems combining PVB with other materials like ionomers or specialized polymers to achieve enhanced moisture protection while maintaining PVB's advantageous optical and mechanical properties.

Types and Grades of Photovoltaic PVB Films

The photovoltaic industry utilizes several distinct categories of PVB interlayer films, each optimized for specific module types, manufacturing processes, or performance requirements. Understanding these categories enables appropriate selection for particular applications.

| PVB Type | Key Features | Best Applications |

| Standard PV-Grade PVB | Balanced performance, proven reliability, cost-effective | General utility-scale modules, standard environments |

| High-Transparency PVB | Enhanced light transmission (>91%), low haze | Premium modules, bifacial panels, BIPV applications |

| Moisture-Resistant PVB | Enhanced moisture barrier, superior edge seal | Humid climates, marine installations, tropical regions |

| UV-Stabilized PVB | Extended UV resistance, minimal yellowing | High-altitude installations, intense solar radiation areas |

| Colored/Tinted PVB | Aesthetic customization, wavelength filtering | BIPV, architectural integration, design-focused projects |

| Thin-Film Compatible PVB | Optimized for CdTe, CIGS, perovskite cells | Thin-film solar technologies, emerging cell types |

Quality Standards and Certification Requirements

Photovoltaic grade PVB interlayer films must meet rigorous quality standards and certification requirements to ensure reliable performance in solar module applications. International standards organizations and industry consortiums have established comprehensive testing protocols that evaluate material properties, aging behavior, and compatibility with solar module manufacturing processes.

The IEC 61215 standard for crystalline silicon terrestrial photovoltaic modules includes numerous tests that indirectly evaluate encapsulation materials including PVB films, such as thermal cycling (200 cycles between -40°C and 85°C), damp heat testing (1000 hours at 85°C and 85% relative humidity), humidity-freeze cycling, and UV preconditioning. While these tests evaluate complete modules rather than isolated materials, PVB films must possess characteristics enabling modules to pass these demanding requirements. Additionally, the IEC 61730 standard addresses module safety qualification, including electrical safety and fire performance, which relates to PVB flame retardancy and electrical insulation properties.

Beyond international standards, leading PVB manufacturers typically obtain third-party certifications from organizations like TUV Rheinland, UL, or other recognized testing bodies. These certifications provide independent verification of material properties, manufacturing consistency, and suitability for photovoltaic applications. When selecting PVB films, prioritize products with comprehensive certification documentation and test reports demonstrating compliance with relevant standards.

Selection Criteria Based on Module Design

Different solar module designs and cell technologies impose varying requirements on PVB interlayer films, necessitating careful material selection aligned with specific module characteristics and performance objectives.

Monofacial vs. Bifacial Module Considerations

Traditional monofacial modules generate power only from their front surface, with opaque backsheets blocking rear-side light. These designs allow more flexibility in PVB selection, as rear-side optical properties matter less than frontal transmission and adhesion to the backsheet. Bifacial modules, which capture light from both front and rear surfaces, require PVB films with exceptional transparency on both sides and compatible with transparent backsheets or glass-glass constructions. The rear-side light transmission directly impacts bifacial gain—the additional energy generated from rear-side illumination—making high-transparency PVB particularly valuable for bifacial applications.

Glass-Glass vs. Glass-Backsheet Construction

Glass-glass modules sandwich solar cells between two glass sheets, often using PVB as the primary encapsulant for both front and rear lamination. This construction demands PVB with excellent glass adhesion, superior moisture barrier properties (since edge sealing becomes more critical), and enhanced mechanical properties to accommodate the rigidity and weight of dual glass construction. Glass-backsheet modules use glass only on the front surface with a polymer backsheet on the rear, requiring PVB that bonds well to both glass and the specific backsheet material, whether polyester-based, fluoropolymer, or other compositions.

Cell Technology Compatibility

Different photovoltaic cell technologies present varying compatibility requirements for encapsulation materials. Crystalline silicon cells (monocrystalline and polycrystalline) work well with standard PV-grade PVB formulations that have been optimized over decades of industry experience. Thin-film technologies including cadmium telluride (CdTe), copper indium gallium selenide (CIGS), and emerging perovskite cells may require specialized PVB formulations addressing specific chemical compatibility, processing temperature limitations, or moisture sensitivity concerns unique to these cell types. Always verify PVB compatibility with the specific cell technology and any specialized coatings or treatments used in the module design.

Environmental and Climate Considerations

The deployment environment significantly influences appropriate PVB selection, as different climates and geographic locations impose varying stress factors on solar modules. Matching PVB characteristics to anticipated environmental conditions optimizes long-term performance and reliability.

- Hot, humid climates: Prioritize moisture-resistant PVB formulations with low water vapor transmission rates and enhanced adhesion retention under humid conditions to combat moisture-induced degradation mechanisms

- Desert environments: Select UV-stabilized PVB with superior resistance to yellowing and degradation under intense solar radiation and high operating temperatures that can exceed 85°C in module interiors

- Cold climates: Choose PVB maintaining flexibility and adhesion at low temperatures while resisting thermal cycling stress from daily and seasonal temperature variations

- Coastal and marine installations: Require PVB with enhanced corrosion resistance and superior edge sealing to prevent salt spray and moisture ingress that accelerates degradation

- High-altitude deployments: Need UV-stabilized formulations addressing increased UV radiation intensity at elevation while handling greater temperature extremes

Manufacturing Process Compatibility

PVB interlayer film selection must account for compatibility with the specific manufacturing equipment and processes used in module fabrication. Lamination process parameters including temperature profiles, vacuum levels, pressure application, and cycle times significantly affect how PVB performs and bonds to other module components.

Standard vacuum lamination processes typically operate at temperatures between 140°C and 150°C with cycle times of 8-15 minutes, parameters that work well with most photovoltaic grade PVB films. However, some advanced or high-throughput manufacturing lines may use modified processes requiring PVB formulations with adjusted processing windows. Fast-cure PVB films enable shorter lamination cycles, increasing production throughput but potentially requiring more precise process control. Some manufacturers offer PVB grades optimized for specific laminator types or configurations, providing superior results when matched to appropriate equipment.

Film handling characteristics also impact manufacturing efficiency and yield. PVB films must resist blocking (sticking together on the roll), maintain dimensional stability during storage and handling, and exhibit consistent thickness across the web width. Films with anti-blocking treatments or optimized plasticizer content facilitate smooth processing and reduce manufacturing defects. Consider the available infrastructure for film storage, as PVB requires controlled humidity conditions to prevent moisture absorption that could affect processing and final module properties.

Cost-Performance Trade-offs and Economic Considerations

PVB interlayer film represents a relatively small percentage of total module material costs, typically 2-4% depending on module design and PVB grade. However, the encapsulation system's contribution to overall module reliability and longevity makes PVB selection a critical economic decision extending beyond simple material cost comparisons.

Premium PVB films with enhanced properties command price premiums of 15-40% compared to standard grades, but may justify their cost through improved module performance, extended warranties, or suitability for demanding applications. For utility-scale projects where energy production determines project economics, investing in high-transparency PVB that increases light transmission by even 0.5-1% can generate significant additional revenue over the module's lifetime, easily offsetting the incremental material cost. Similarly, superior moisture resistance reducing degradation rates can preserve energy production and extend module life, improving long-term project returns.

Conversely, for cost-sensitive residential or commercial markets, standard PV-grade PVB offering proven reliability at lower cost may represent the optimal choice when premium performance characteristics aren't essential for the application. The key is analyzing total cost of ownership rather than focusing solely on initial material cost—considering factors including expected module lifetime, warranty requirements, maintenance costs, and energy production over the project's economic life.

Leading Manufacturers and Supply Chain Considerations

The global photovoltaic grade PVB market includes several established manufacturers with proven track records in solar applications. Major suppliers include Eastman Chemical Company (Saflex Solar), Kuraray (Trosifol), Sekisui Chemical (S-LEC), and several Chinese manufacturers who have developed photovoltaic-specific product lines. Each manufacturer offers multiple product grades targeting different performance levels, applications, and price points.

When selecting PVB suppliers, evaluate factors beyond just material specifications and pricing. Consider the supplier's technical support capabilities, including assistance with process optimization, troubleshooting, and product selection for specific applications. Established suppliers typically provide comprehensive technical data sheets, application guides, and processing recommendations developed through extensive industry experience. Manufacturing consistency and quality control systems are critical, as variations in film properties between batches can affect module quality and manufacturing yields.

Supply chain reliability has become increasingly important in the volatile global materials market. Assess supplier financial stability, manufacturing capacity, geographic distribution of production facilities, and ability to provide consistent supply during periods of high demand or supply chain disruptions. Some module manufacturers establish long-term supply agreements or qualify multiple PVB suppliers to ensure material availability and competitive pricing while maintaining flexibility to adapt to changing market conditions or performance requirements.

Testing and Quality Verification Procedures

Implementing robust testing and quality verification procedures ensures that PVB interlayer films meet specifications and perform consistently in production. Module manufacturers should establish incoming material inspection protocols verifying critical properties including optical transmission, thickness uniformity, moisture content, and physical appearance. Simple tests like visual inspection for defects, thickness measurement using micrometers, and verification of proper packaging and storage conditions should be performed on every batch received.

More comprehensive testing on periodic samples or new material batches might include peel adhesion testing after lamination, accelerated aging tests simulating long-term environmental exposure, and optical property measurements using spectrophotometers. Maintaining test records creates a quality history enabling identification of material variations or trends that might affect module performance. For critical projects or when qualifying new PVB suppliers, consider third-party testing by accredited laboratories providing independent verification of material properties and suitability for photovoltaic applications.

Future Trends and Emerging Technologies

The photovoltaic PVB market continues evolving in response to advancing solar technologies, changing market demands, and environmental considerations. Several trends are shaping the future development of PVB interlayer films for solar applications.

Sustainability and recyclability are receiving increased attention as the solar industry addresses end-of-life module management. Researchers are developing PVB formulations facilitating easier module disassembly and material recovery, potentially incorporating bio-based plasticizers or modified polymer compositions that maintain performance while improving environmental profiles. Some emerging approaches explore reversible adhesion systems allowing non-destructive module disassembly for component reuse or recycling.

Functional encapsulants represent another innovation direction, with researchers investigating PVB films incorporating additional capabilities beyond basic encapsulation. Examples include luminescent materials that shift UV light to wavelengths better utilized by solar cells, cooling additives that reduce module operating temperatures, or electrical properties enabling PVB to participate in module electrical performance rather than simply providing mechanical protection. While these advanced concepts are still largely developmental, they indicate potential future directions for photovoltaic encapsulation technology where PVB films contribute more actively to module energy generation and thermal management.

English

English 中文简体

中文简体