Our Categories

Architectural Glass PVB Interlayer Film Manufacturers

-

ATL PVB 100% resin Architectural

-

ATL PVB Luminous White Series

-

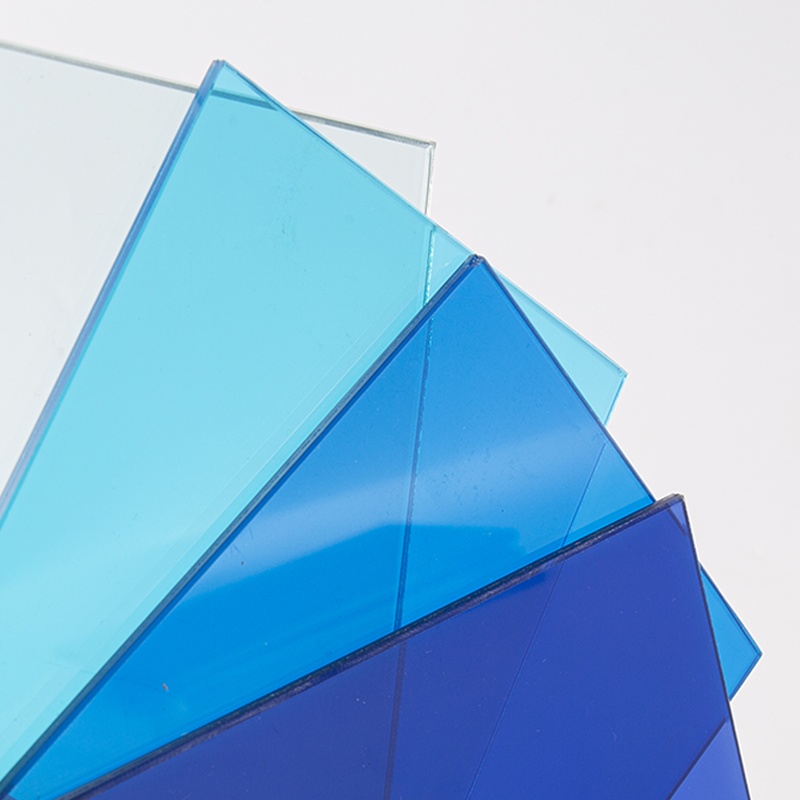

ATL PVB Color Architectural

-

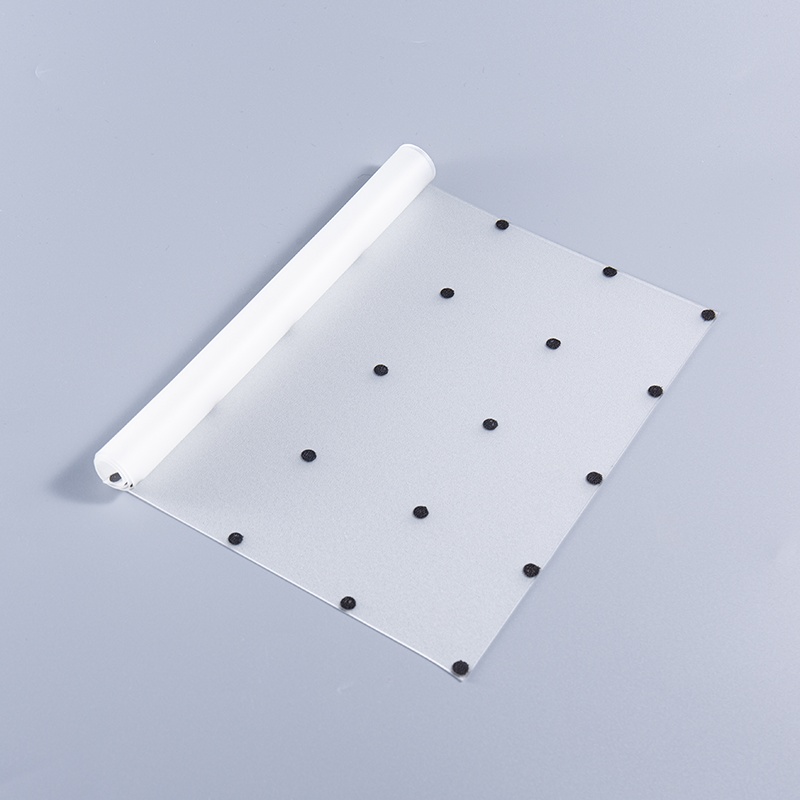

ATL PVB ARCHITECTURAL Bird-Safe Series

-

ATL PVB ARCHITECTURAL Acoustic Series

-

ATL PVB ARCHITECTURAL Gradient Series

Architectural PVB Interlayer Film refers to a Polyvinyl Butyral (PVB) film used primarily as a safety and performance-enhancing layer in laminated architectural glass. It is widely used in building facades, windows, skylights, railings, curtain walls, and canopies.PVB (Polyvinyl Butyral) is a resin typically sandwiched between two layers of glass to form laminated safety glass. It’s a soft, adhesive material that bonds strongly to glass surfaces and maintains its integrity after impact.Holds broken glass fragments together upon impact.Reduces risk of injury during breakage.Provides resistance to burglary or forced entry.

Standard PVB – For basic safety and clarity.

Colored/Tinted PVB – For decorative or shading applications.

UV-cut PVB – For enhanced protection against sun damage.

Soundproofing (Acoustic) PVB – For noise-sensitive environments like studios, hospitals, or hotels.

If you want, I can help with supplier recommendations, technical specifications, or suggest the right PVB film type for a specific architectural project. Just let me know!

COMPANY

About ATL

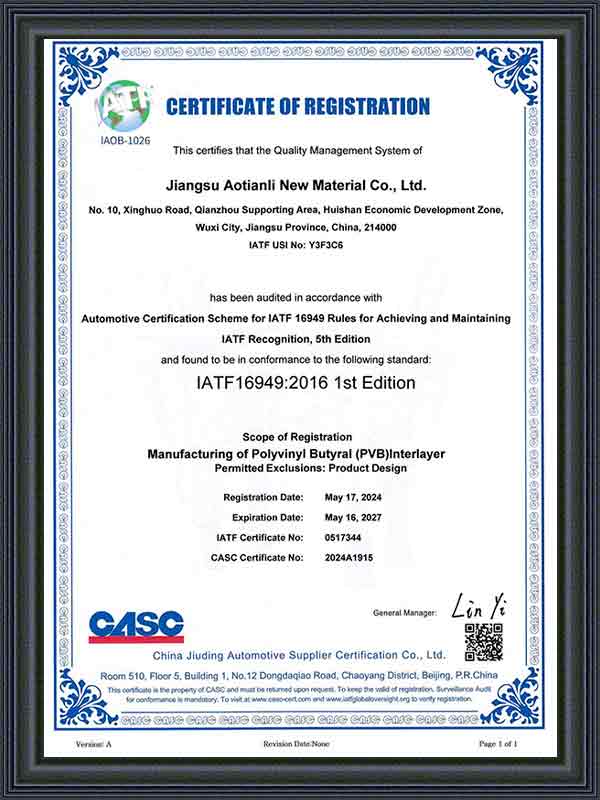

Jiangsu Aotianli New Material Co., Ltd.

Established in 2014 and headquartered in Wuxi, Jiangsu Province, Jiangsu Aotianli New Material Co., Ltd. (ATL) is a company specializing in the research, development, production, and sales of high-performance PVB interlayer films. As Architectural Glass PVB Manufacturers and Architectural PVB Interlayer Film Solutions in China, with an advanced production process, continuous technological innovation, and a complete supply chain layout, ATL has established an important position in both domestic and international PVB interlayer film markets.

With the acquisition of Jiangxi Tianhui New Materials Co., ATL has formed a complete industrial chain from PVB resin to intermediate films, ensuring a stable supply of raw materials. Supply Wholesale PVB Interlayer for Architecture Glass. At the same time, through its foreign trade company Shanghai Zhihe Industrial Co., Ltd. (Zhihe), ATL's products are exported to European, North American, and Asian markets, enjoying a good reputation in the international market.

latest news

ATL News

-

The Best PVB Interlayer Film for Your Needs ---2026.02.04Polyvinyl butyral (PVB) interlayer film has become an essential component in modern photovoltaic systems, serving as a critical bonding layer between glass panels and solar cells. This specialized fil...

-

What Is Automotive Acoustic PVB Interlayer and How Does It Reduce Vehicle Noise? ---2026.01.30Overview of Automotive Acoustic PVB Interlayer Automotive Acoustic Polyvinyl Butyral (PVB) interlayer is a specialized polymer film used in laminated automotive glass to significantly reduce noise tra...

Industry Knowledge

High-Performance Architectural PVB Interlayer Film for High-Rise Glazing Systems

In the modern urban landscape, high-rise buildings dominate skylines and demand advanced materials to meet architectural, safety, and energy-efficiency requirements. One critical component in high-rise glazing systems is the Architectural PVB (Polyvinyl Butyral) Interlayer Film, which provides structural integrity, impact resistance, sound insulation, and ultraviolet protection to laminated glass. Among the key global players in this field, Jiangsu Aotianli New Material Co., Ltd. (ATL) stands out with its cutting-edge products, robust supply chain, and strong international presence.

Leading the Future of PVB Interlayer Technology

Established in 2014 and headquartered in Wuxi, Jiangsu Province, ATL specializes in the research, development, production, and sales of high-performance PVB interlayer films. These films are a fundamental element in laminated safety glass used across architectural, automotive, and photovoltaic sectors. For architectural applications, ATL’s Architectural PVB Interlayer Film is engineered to deliver superior performance in high-rise glazing systems—structures where safety, transparency, thermal performance, and aesthetic appeal are non-negotiable.

ATL’s focus on continuous innovation and quality improvement has earned it a prominent position in both domestic and international markets. The company utilizes advanced manufacturing processes and automated quality control systems to ensure each roll of PVB film meets the highest standards in clarity, durability, and adhesion.

A Fully Integrated Industrial Chain

To ensure consistent product quality and supply stability, ATL has strategically built a vertically integrated industrial chain. With the acquisition of Jiangxi Tianhui New Materials Co., Ltd., ATL now controls the full production process from PVB resin to interlayer film. This end-to-end control allows the company to maintain strict quality standards, optimize production efficiency, and respond swiftly to client needs and market changes.

The production of Architectural PVB Interlayer Film begins with the synthesis of high-purity PVB resin. This resin is then processed into interlayer films under precisely controlled conditions, resulting in products that provide outstanding optical transparency, strong adhesion to glass, and long-term stability under extreme weather conditions—all essential for high-rise glazing.

Applications in High-Rise Glazing Systems

The architectural applications of ATL’s PVB interlayer films are extensive. High-rise buildings use laminated safety glass with PVB films to enhance both structural performance and occupant safety. When used in façades, curtain walls, and skylights, ATL’s Architectural Glass PVB contributes to:

Impact resistance: The film holds shattered glass in place in the event of breakage, reducing the risk of injury and protecting building occupants.

Sound insulation: The interlayer dampens sound transmission, making it ideal for buildings in busy urban environments.

UV protection: The film blocks over 99% of harmful ultraviolet rays, protecting interior furnishings and occupants from UV-related damage.

Energy efficiency: Certain formulations can enhance solar control and thermal insulation, reducing HVAC loads.

Aesthetic versatility: Available in clear, tinted, or colored versions, the film allows architects to design visually striking façades without compromising safety.

These qualities make ATL’s Architectural PVB Interlayer Film an ideal solution for buildings facing harsh environmental stress, such as strong wind loads, seismic activity, or extreme temperature variations.

Global Reach and Strategic Export

ATL’s commitment to global growth is reinforced through its international arm, Shanghai Zhihe Industrial Co., Ltd., which handles overseas marketing and logistics. Through Zhihe, ATL exports its high-performance Architectural PVB Interlayer Film to Europe, North America, and Asia, where it enjoys a strong reputation for reliability, consistency, and innovation.

International customers rely on ATL not only for product quality but also for its responsive technical support and customized solutions. The company collaborates closely with glass fabricators, architects, and contractors to develop PVB films tailored to specific project requirements. This customer-centric approach has helped ATL build long-term relationships with leading partners in the global construction and glass processing industries.

Commitment to Sustainability and Compliance

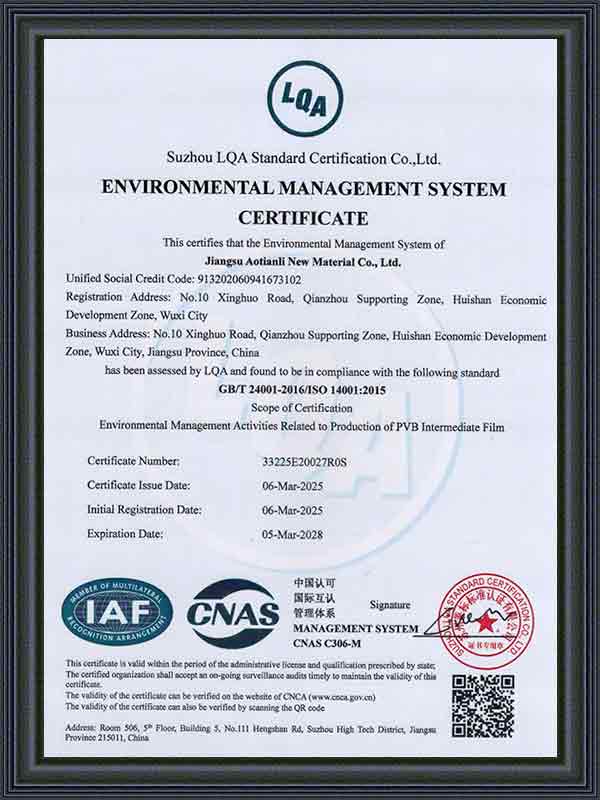

In an era when sustainability is a global priority, ATL is committed to environmentally responsible manufacturing. The company follows strict environmental protection policies, uses eco-friendly production technologies, and ensures that all its Architectural PVB Interlayer Films comply with relevant international safety and environmental standards, including EN, ASTM, and ISO certifications.

By developing formulations that extend the lifecycle of laminated glass, reduce energy consumption, and promote indoor comfort, ATL contributes to the creation of green, sustainable urban spaces.

Looking Ahead

As urbanization accelerates and building codes become increasingly stringent, the demand for high-performance materials like ATL’s PVB Interlayer for Architecture Glass is expected to grow. The company continues to invest heavily in R&D, aiming to further improve the mechanical properties, acoustic performance, and multifunctionality of its products.

With its complete industrial chain, global export network, and dedication to innovation, Jiangsu Aotianli New Material Co., Ltd. is well-positioned to shape the future of architectural safety glass. Whether in the skyline of New York, the towers of Dubai, or the business districts of Shanghai, ATL’s Architectural PVB Interlayer Films are helping to build a safer, more beautiful, and more sustainable world.

English

English 中文简体

中文简体