Our Categories

Automotive Glass PVB Interlayers Manufacturers

-

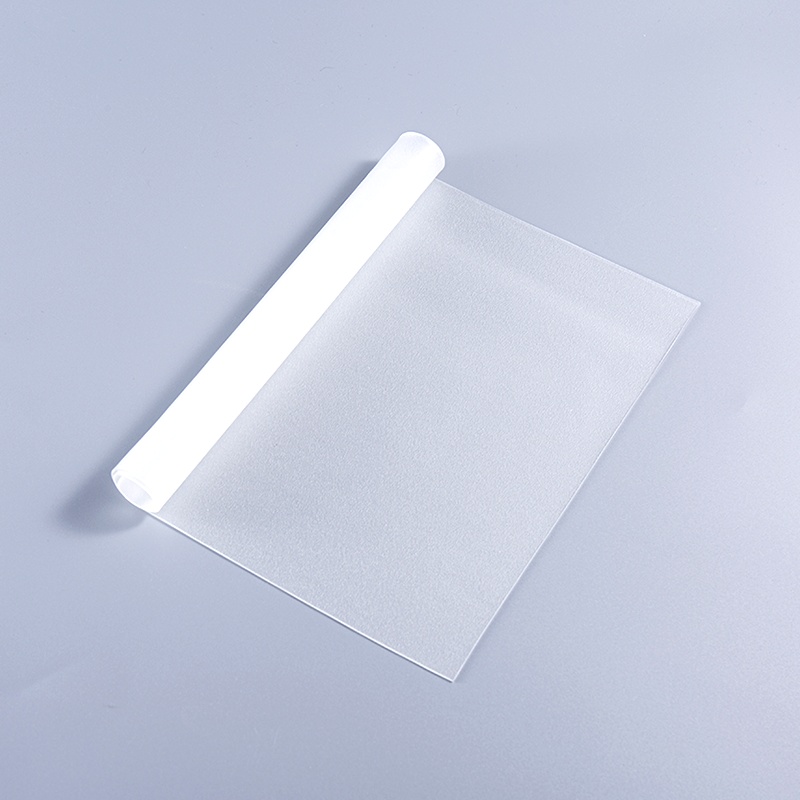

ATL PVB AUTOMOTIVE Clear

-

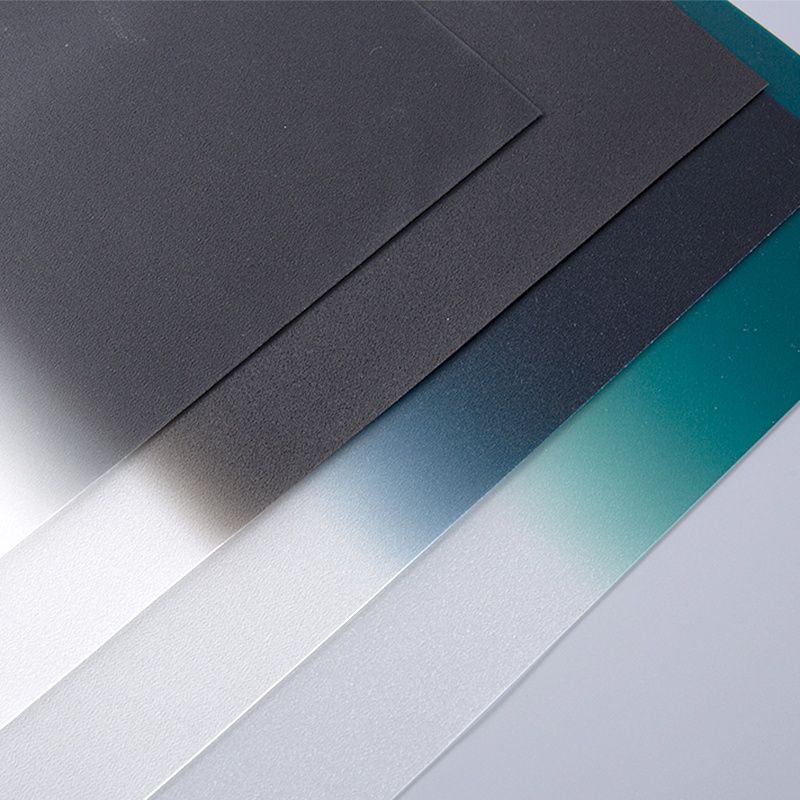

ATL PVB Gradient Windshield

-

ATL PVB Heat Insulation Series

-

ATL PVB AUTOMOTIVE Acoustic Series

-

ATL PVB AUTOMOTIVE HUD Series

-

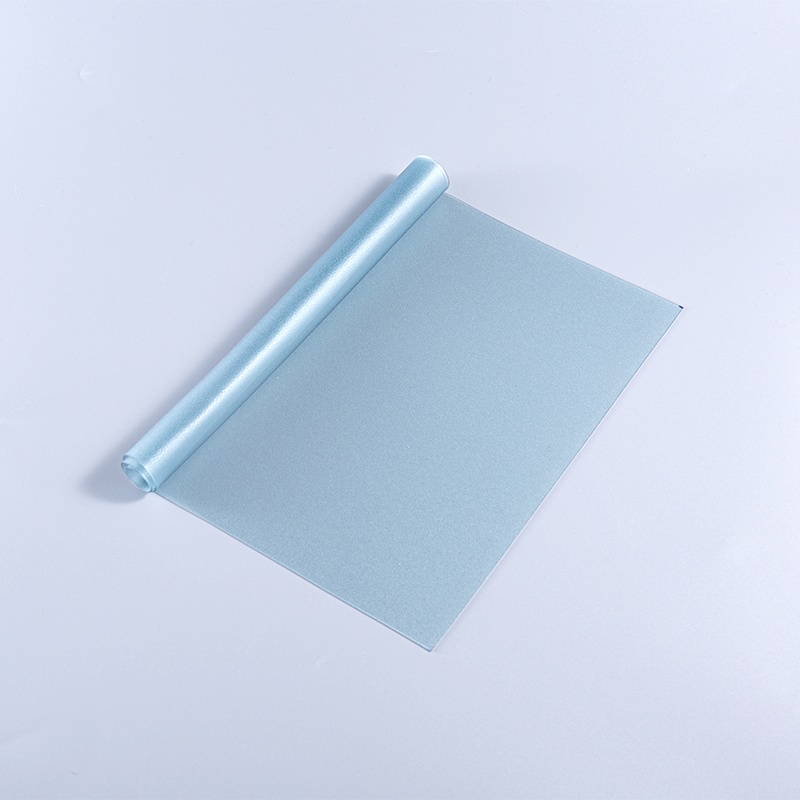

ATL PVB AUTOMOTIVE Color Series

Automotive PVB Interlayer Film is a specialized Polyvinyl Butyral (PVB) material used in the laminated windshields and other glass components of vehicles. It’s designed to enhance safety, comfort, acoustic control, and UV protection in automotive glass systems.

Prevents the glass from shattering into sharp shards during an accident.The broken glass adheres to the PVB, reducing injury risk.

Special acoustic PVB films block or reduce road and wind noise.

Enhances cabin comfort and quietness.Helps preserve interior components (dashboard, seats) from fading.Makes it harder to break through the glass in theft or vandalism attempts.Available in clear, tinted, and colored versions to match vehicle styling.Supports heads-up display (HUD) and advanced driver-assistance systems (ADAS) compatibility.

COMPANY

About ATL

Jiangsu Aotianli New Material Co., Ltd.

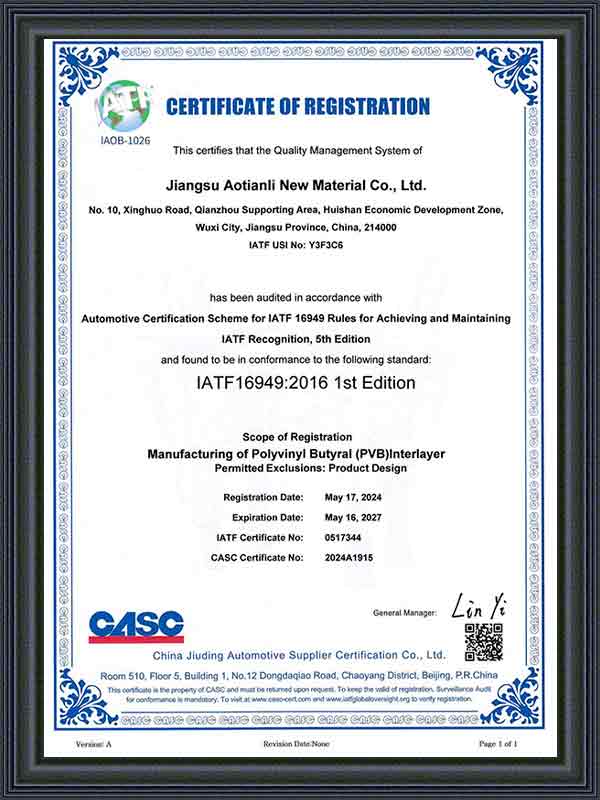

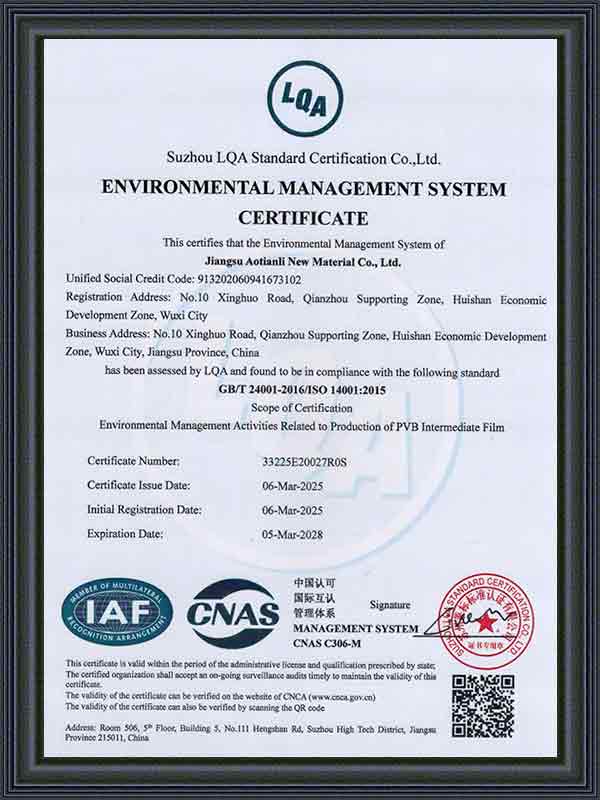

Established in 2014 and headquartered in Wuxi, Jiangsu Province, Jiangsu Aotianli New Material Co., Ltd. (ATL) is a company specializing in the research, development, production, and sales of high-performance PVB interlayer films. As Automotive Laminated Glass PVB Interlayers Manufacturers and Automotive PVB Film Company in China, with an advanced production process, continuous technological innovation, and a complete supply chain layout, ATL has established an important position in both domestic and international PVB interlayer film markets.

With the acquisition of Jiangxi Tianhui New Materials Co., ATL has formed a complete industrial chain from PVB resin to intermediate films, ensuring a stable supply of raw materials. Supply Wholesale PVB Film for Car Windshield. At the same time, through its foreign trade company Shanghai Zhihe Industrial Co., Ltd. (Zhihe), ATL's products are exported to European, North American, and Asian markets, enjoying a good reputation in the international market.

latest news

ATL News

-

The Best PVB Interlayer Film for Your Needs ---2026.02.04Polyvinyl butyral (PVB) interlayer film has become an essential component in modern photovoltaic systems, serving as a critical bonding layer between glass panels and solar cells. This specialized fil...

-

What Is Automotive Acoustic PVB Interlayer and How Does It Reduce Vehicle Noise? ---2026.01.30Overview of Automotive Acoustic PVB Interlayer Automotive Acoustic Polyvinyl Butyral (PVB) interlayer is a specialized polymer film used in laminated automotive glass to significantly reduce noise tra...

Industry Knowledge

Automotive Glass PVB Interlayers: Improved impact strength and sound insulation performance

In the modern automotive industry, safety, comfort, and performance are key factors that drive innovation in vehicle design. One of the most critical components contributing to these aspects is the laminated glass used in windshields and other windows, which relies on Polyvinyl Butyral (PVB) interlayers. These interlayers play a vital role in enhancing impact resistance, maintaining structural integrity, and improving sound insulation in automotive applications.

Jiangsu Aotianli New Materials Co., Ltd. (ATL), established in 2014 and headquartered in Wuxi, Jiangsu Province, has emerged as a leading manufacturer of high-performance Automotive Glass PVB Interlayers. With a strong focus on research, development, production, and sales, ATL has positioned itself as a key player in both domestic and international markets through continuous technological innovation and an advanced production process.

The Role of Automotive Glass PVB Interlayers

PVB interlayers are essential in laminated safety glass due to their excellent adhesion to glass, optical clarity, and ability to absorb energy upon impact. In automotive applications, Automotive Glass PVB Interlayers serve multiple functions:

Impact Resistance : When a windshield is struck by debris or involved in a collision, the PVB layer absorbs much of the force, preventing the glass from shattering into dangerous shards.

Safety : Even if the outer glass layers break, the PVB interlayer holds them together, reducing the risk of injury to passengers.

Sound Insulation : The viscoelastic properties of PVB help dampen noise, significantly improving acoustic comfort inside the vehicle cabin.

UV Protection : PVB films block more than 99% of ultraviolet radiation, protecting both passengers and interior materials from sun damage.

Technological Advancements by ATL

Jiangsu Aotianli New Materials Co., Ltd. has consistently invested in R&D to enhance the performance of its PVB Film for Car Windshield. By optimizing polymer formulations and refining lamination processes, ATL ensures that its products deliver superior mechanical strength and acoustic insulation without compromising transparency or durability.

One of the major breakthroughs achieved by ATL is the development of multilayer PVB films with graded acoustic damping properties. These advanced interlayers can effectively reduce road and engine noise across a wide range of frequencies, making them ideal for luxury vehicles and electric cars where quiet interiors are particularly valued.

Moreover, ATL’s Automotive Glass PVB Interlayers meet stringent international standards such as ANSI Z26.1, ECE R43, and GB9656, ensuring compliance with global quality and safety requirements.

Integrated Supply Chain Enhancing Quality and Stability

A significant advantage that sets ATL apart in the competitive market is its vertically integrated supply chain. Through the acquisition of Jiangxi Tianhui New Materials Co., ATL now controls the entire production chain—from raw PVB resin to finished interlayer films. This integration not only guarantees a stable supply of high-quality raw materials but also allows for tighter control over product consistency and cost efficiency.

Additionally, ATL leverages its foreign trade subsidiary, Shanghai Zhihe Industrial Co., Ltd. (Zhihe), to distribute Automotive Glass PVB Interlayers to European, North American, and Asian markets. Thanks to this strategic layout, ATL has built a strong international reputation for reliability, technical support, and customer service.

Sustainability and Future Outlook

As environmental concerns become increasingly important, ATL is committed to developing eco-friendly Automotive Glass PVB Interlayers. The company is actively exploring bio-based resins and recyclable materials to reduce the carbon footprint of its products while maintaining high performance.

Furthermore, with the rise of autonomous driving and smart vehicles, the demand for advanced glazing solutions is growing. ATL is well-positioned to meet this evolving need by integrating smart functionalities—such as conductivity, thermal regulation, and electromagnetic shielding—into its PVB interlayers.

PVB Film for Automotive Glass have become indispensable in modern vehicle manufacturing due to their unmatched contributions to safety, comfort, and performance. As a pioneer in this field, Jiangsu Aotianli New Materials Co., Ltd. continues to lead the way with innovative solutions, a robust supply chain, and a commitment to excellence. With its expanding global presence and forward-looking R&D strategy, ATL is poised to shape the future of automotive glazing technology.

English

English 中文简体

中文简体